EPS and XPS solutions Services

Material Optimization

Smart Material Optimization

Maximizing Efficiency with EPS & XPS Solutions

Efficiency Through Smart Material Use

Applications Across Multiple Industries

Efficient EPS & XPS Solutions

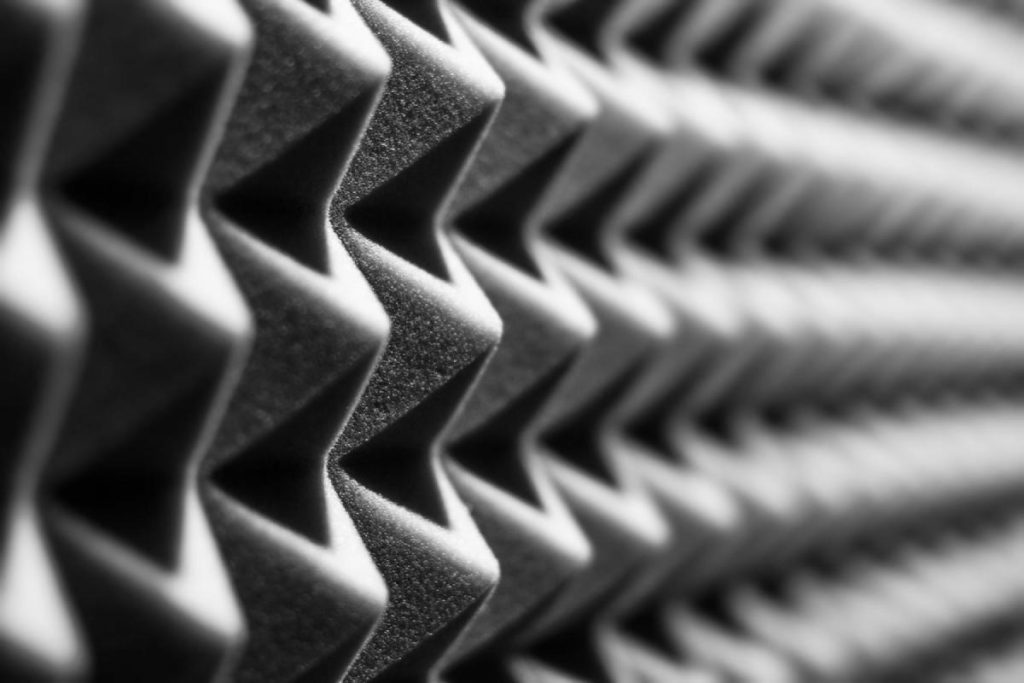

At Class Eps, we are dedicated to delivering high-performance EPS and XPS solutions that maximize efficiency, sustainability, and durability across various industries. Our advanced materials are engineered to provide superior insulation, impact resistance, and long-term reliability, ensuring that every application benefits from cost-effective and energy-efficient solutions. Whether for construction, protective packaging, or industrial use, our EPS and XPS solutions offer lightweight strength and optimized thermal performance, reducing operational costs and improving overall functionality.

By integrating cutting-edge manufacturing techniques, we enhance the strength, durability, and resource efficiency of EPS and XPS materials, making them ideal for diverse applications. Their low thermal conductivity ensures effective insulation, helping businesses reduce energy consumption while maintaining stable internal temperatures.

Smart Material Efficiency

At Class Eps, we believe that maximizing efficiency starts with smart material utilization. By optimizing the use of EPS and XPS, we ensure that every resource is used effectively and sustainably, reducing waste while maintaining high-performance insulation, durability, and structural integrity. Our commitment to precision engineering allows us to develop lightweight, strong, and thermally efficient materials that enhance energy savings and long-term reliability in various industries.

Our approach to smart material utilization enhances energy efficiency, cost-effectiveness, and environmental responsibility across multiple applications. By reducing material waste and improving production efficiency, we help businesses lower operational costs while maintaining high insulation performance. Additionally, our EPS and XPS solutions enhance product protection and energy efficiency, making them ideal for sustainable building and packaging

Industry-Wide Applications

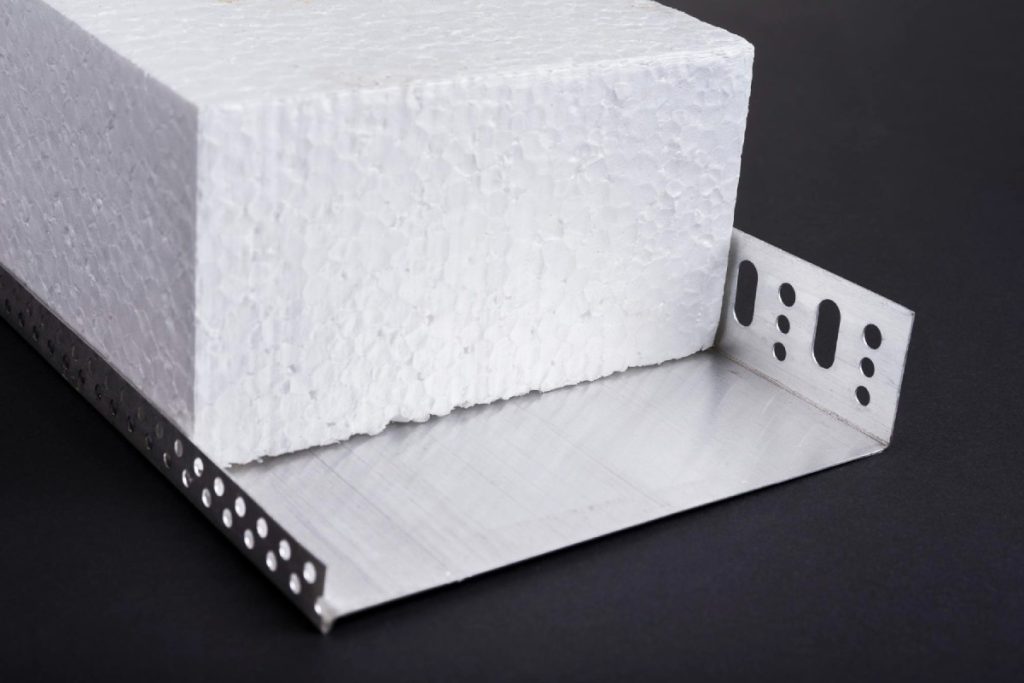

EPS and XPS solutions are used across multiple industries due to their versatility, durability, and high-performance insulation. Their lightweight yet strong composition makes them ideal for construction, packaging, and industrial applications, providing energy efficiency, impact resistance, and cost-effective solutions.

In the construction sector, these materials enhance thermal insulation, moisture resistance, and structural stability, ensuring long-lasting performance in walls, roofs, and foundations. In packaging, they offer shock absorption and temperature control, protecting fragile, medical, and perishable products during transit and storage. Additionally, EPS and XPS play a crucial role in industrial manufacturing, where precision-molded components, protective casings, and custom insulation solutions are required. Their ability to be customized for various needs makes them an efficient and sustainable choice for modern industries.

Eco-Friendly & Affordable Insulation

EPS and XPS insulation provide a sustainable and cost-effective solution for various industries, ensuring energy efficiency and long-term savings. Their lightweight yet durable structure reduces material waste and energy consumption, making them a smart choice for eco-conscious businesses. By integrating advanced manufacturing techniques, these materials help lower environmental impact while maintaining high insulation performance. Designed to offer high thermal insulation and moisture resistance, EPS and XPS help maintain indoor temperature stability, reducing the need for excessive heating and cooling.

This results in lower energy bills and a reduced carbon footprint, making buildings more environmentally friendly and efficient. Their resistance to mold and water damage further ensures long-lasting performance, reducing maintenance costs over time. Beyond construction, EPS and XPS support sustainable packaging, offering recyclable, durable, lightweight materials that reduce waste and costs.

Innovative Industry Applications

EPS and XPS solutions are widely used across modern industries, offering versatile, high-performance materials for construction, packaging, and industrial applications. Their lightweight, durable, and insulating properties make them essential for energy-efficient buildings, protective packaging, and custom industrial components.

In construction, these materials provide superior thermal insulation, reducing energy costs and improving indoor comfort. Their moisture resistance and long-lasting durability make them ideal for walls, roofs, and flooring applications, ensuring structural stability over time. Beyond buildings, EPS and XPS enhance packaging and industrial sectors, offering shock absorption, temperature control, and impact resistance. Their custom-molded, precision-cut design makes them ideal for protecting fragile goods, medical supplies, and industrial components, enhancing efficiency and sustainability.

What we do

EPS & XPS Services

Material optimization enhances efficiency, reduces waste, and improves performance in construction, packaging, and insulation using advanced EPS and XPS solutions.

Custom polystyrene solutions offer lightweight, durable insulation, protection, and flexibility for construction, packaging, and industry using EPS and XPS.

Thermal insulation reduces heat transfer, enhancing efficiency, comfort, and sustainability in buildings, industry, and packaging using EPS and XPS materials.

Custom polystyrene solutions provide lightweight, durable insulation and protection for construction, packaging, and industry using EPS and XPS

Decorative panels enhance aesthetics, insulation, and durability, offering versatile solutions for interiors, exteriors, and architecture using EPS and XPS.

EPS & XPS packaging provides lightweight, durable protection, ensuring safety, insulation, and sustainability for food, medical, and electronics.

Enhance Efficiency and Sustainability with EPS & XPS Solutions

EPS & XPS solutions provide superior insulation, durability, and lightweight efficiency, making them ideal for construction, packaging, and industrial applications while ensuring sustainability and cost-effectiveness